Artikel

What you need to know about the potential market disruption caused by precision fermentation

The concern and need for more sustainable practices are growing globally. Gen Y and Gen Z, who demonstrate strong support for companies that prioritize sustainability over convenience and price, have the power to spread the voice and share companies’ values through the internet. In the last decades, precision fermentation, a well-known technology in the pharma-sector, has emerged as a promising sustainable technology in the food industry, which has successfully been applying it e.g. since the 90’s for fermentation-produced chymosin, a rennet-substitute in cheese making process. The technology has been in use for decades to produce molecules such as enzymes, insulin, vitamins, chymosin, but in recent years the application and potential of precision fermentation has been extended to other food ingredients.

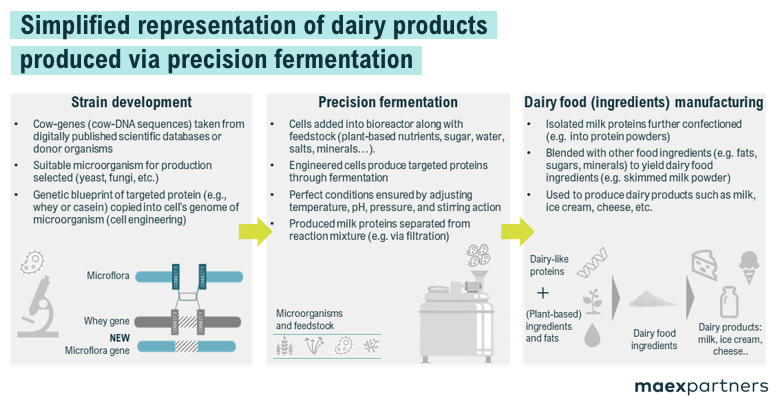

Ever since the COVID pandemic we noticed an exponential growth of newborn start-ups in the precision fermentation business, producing meat-, egg-, fish-, dairy-proteins. Via precision fermentation, genetically modified microorganisms (GMOs) produce target compounds like essential animal-proteins without conventional agriculture or animal farming. First, animal DNA-genes are inserted into microorganisms‘ DNA. They are then left to “ferment” in a fermentation tank under controlled conditions, producing the desired product. In the end, the genetically modified microorganisms are removed, leaving the isolated target molecule GMOs-free. This technique offers several advantages and a few disadvantages:

Pros of Precision Fermentation

- Sustainability: It has proven to be more environmentally friendly than conventional agriculture, meat, or dairy industries, being lower in greenhouse gas emissions, in energy demand, in water consumption.

- Animal welfare: It eliminates animal farming and consequently ethical concerns related to animal suffering.

- Customization and nutrition: It allows tailoring nutrient composition to meet specific dietary needs, e.g., lactose-free diets.

- Simplification of the supply chain: By an in-house production of essential nutrients and proteins, big importers could “domesticize” production, cutting some external costs, and increase potential cost-competitiveness.

Bottlenecks of Precision Fermentation

- Limited expertise in scale-up and high capex: Although being applied for 30 years in the production of rennet-substitute and insulin, scale-up of fermentation processes to meet industrial food quantities at low-cost levels is still challenging due to several capex-intensive batch-type reaction, solid-handling, and purification steps. Spacetime yield must be significantly improved to become cost competitive.

- Long approval process in regulated markets: In some attractive markets like the EU, the approval process for precision fermentation products is long and still not always clear, demotivating food producers to support the extension of precision fermentation in food production.

- GMOs-concern: Consumers are influenced by conflicting messages from the traditional industry and a lack of accurate information, leading to the misconception that fermentation-based proteins inherently contain GMOs.

Nevertheless, as precision fermentation continues to evolve, it disrupts traditional food production methods: recent research, conducted among UK dairy consumers, shows that if animal-free dairy products would be commercialized today, at price-parity with traditional dairy products, 33% of the interviewed would buy them as first choice. Moreover, expert opinions and start-ups are sure to reach price competitiveness within three to five years.

Singapore, Israel and the US are leading the way in the precision fermentation market: several restaurants and pizzerias, as well as brands such as Nestlé, Mars, Unilever, Bel, etc. have active collaborations with start-ups that produce proteins via precision fermentation (e.g., Remilk, Formo, Perfect Day, New Culture, Good Meat, Farmless…), and already launched animal-free products on the market or on their menus. Europe will follow shortly: the recent official approval in the Netherlands of tasting of cultivated meat in controlled environment, and the first submission for approval of cultivated meat in Switzerland and UK, represent two first milestones along the path of commercialization of novel food.

Take aways for traditional food producers

Food producers should ask themselves what the short- and long-term future of traditional food production methods will look like. Will precision fermentation be as cheap as announced in such near future? Will the traditional industry be replaced? What is the proper strategy to survive in this highly disruptive market environment?

While individual strategies can be versatile due to market situations, portfolio mix, corporate culture, risk appetite and shareholder structures with divergent interests, we recommend first and foremost developing a core belief that is supported throughout the organization and then consistently worked towards. A food producer should well understand the potential and implication of precision fermentation, for example where exactly fermentation-based proteins could be introduced along the product value chain and whether this would require a change in the existing assets and capabilities. Market entry options along the value chain are manifold and vary from the complete development of all competencies, joint venture, or partnership strategies to simple supplier-customer relationships.

It certainly will be a challenge to move successfully in the field of tension between different and yet unknown scenarios. However, remaining hesitant or even still will lead to losing significant market shares. We are happy to navigate through these challenges with you and are looking forward to putting our heads together to figure out customized strategies on how to embrace the opportunities and tackle the threats that come with precision fermentation.

If you are interested in further discussing this topic please feel free to reach out to Michael Dürr or Dr. Valentina Bragoni.